Low Profile Industrial Top Plate Locking Caster Wheels with Brake

KT-LGP1-63RF

Detailed description of castor rubber coating

Different base materials shall be coated with different materials.

For example, PP can not be wrapped

with ABS, ABS can not be wrapped with PA, etc. At present, the

rubber coated TPE in the market can

be divided into the following categories: PP rubber coated, ABS

rubber coated, PETG rubber coated,

PC rubber coated, PA rubber coated, etc.

Thickness of TPE coating:

In most rubber coated molding applications, good bonding effect can

be guaranteed when the wall

thickness range is 1.5-3.0mm. If the TPE glue position is too thin,

injection molding is difficult, the

bonding strength is low and the hand feel is poor. If the TPE glue

position is too thick, on the one

hand, the cost is high, on the other hand, it is easy to produce

shrinkage, bubbles and other defects.

The wall thickness of TPE glue position shall be as uniform as

possible to achieve the best forming

cycle. The transition between different wall thicknesses should be

gradual to reduce problems caused

by fluid flow, such as gas ripples and bubbles.

Radian (minimum radius 0.5mm) shall be used at sharp corners to

reduce local stress. Deep closed

air chambers or arched parts that cannot be vented shall be

avoided. If necessary, enough exhaust

slots (0.015-0.025mm) can be added at the end of TPE glue position.

Insufficient exhaust may cause

gas trapping, glue burning, insufficient adhesion and other adverse

phenomena.

It is helpful to improve the bonding effect of TPE by adding buckle

on the substrate or making some

properly designed deep concave convex parts. Treatment of die

surface:

The mould shall be polished to obtain a smooth or clear surface. In

order to produce the dull

appearance of thermosetting rubber surface, a rough mold surface is

needed. Generally speaking,

the rough surface of the die cavity after electrical discharge

machining (EDM) will produce a good

workpiece appearance and make demoulding easier. Grinding methods

such as steam jet, sand blast

or shot peening and chemical etching can also be used to produce

surfaces with different gloss and

appearance.

In order to facilitate demoulding, a layer of demoulding coating

can be applied on the mold cavity or

core, for example, a layer of nickel impregnated with PTFE

(polytetrafluoroethylene) after sand blasting

or electrical discharge machining (EDM).

The use of release agent shall be avoided for the base material.

The surface of the substrate shall be

clean and avoid contacting dust as much as possible.

The processing temperature of TPE compound shall be subject to the

measured melting temperature

of the compound, rather than the displayed temperature of the

injection molding machine.

If TPE is required to be coated on metal parts, appropriate

adhesive can be used as an auxiliary.

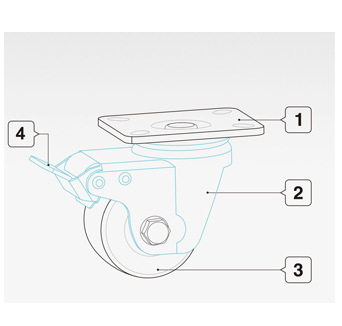

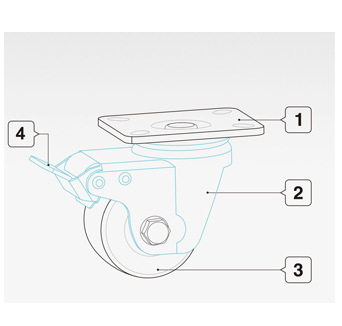

Industrial Swivel Casters Parameter

| Wheel material | Nylon6 |

| Load Capacity | 600KG |

| Wheel Diameter | 63mm |

| Color | white |

| Tread Width | 50mm |

| Load Height | 96MM |

Industrial Swivel Casters Describe

Industrial Swivel Casters Size

Industrial Swivel Casters Material

| Name | Material | Treatment |

| 1 | Caster Seat | Cold-rolled carbon steel | Black Coated/Zn Galvanized |

| 2 | Body | Aluminum alloy | Ivory/Powder Coated |

| 3 | Ball | Bearing Steel | Ni-Cr |

| 4 | Brake | Steel 45 | Zn Galvanized |

| 5 | Pin | Steel 10 | Zn Galvanized |

| 6 | Wheel | PA6 | Black |

Industrial Swivel Casters Scope of application

Application.

Communication equipment, semiconductor manufacturing equipment,

experimental equipment,

medical equipment, printing machines, all kinds of Press, all kinds

of special machinery, all kinds

of variable production equipment, dust-free room equipment,

aluminum frame, equipment, etc.

About us.

KTC (Bejing Korea Technology Caster Co., Ltd.) was founded in 2007.

KTC is a modern

company specialzingin the production of multi function &high

quality CASTER and

KT FOOT based on best design and design technology.

KTC.

The company is headquartered in Niulanshan Industrial Zone,Shunyi

District, Beijing. KTC

adopts international advanced production testing equipments,

professional intelligent

production management system and professional design flow. Now the

company produces

multi function & high quality production, such as KT CASTER and KT

FOOT, among which

high quality of height adjusting CASTER,shockproof type CASTER,

high quality of height

adjusting CASTER, shockproof type CASTER,high load CASTER and level

adjusting FOOT

are widely used in the world's advanced automation equipment and

semiconductor e

quipment industry.

In order to manufacture the world's highest level of products,KTC

use the best processing

technology and equipment. And KTC continuously launches world top

level of new products.

KTC's s also has set up a branch in Korea, so it is favored by

theusers of various fields around

the world.