Low Profile Industrial Top Plate Locking Caster Wheels with Brake

KT-LGP1-75RF

Control and detection of galvanizing process for casters

(1) Three links that should be strictly controlled in electro

galvanizing of caster Hardware:

1. Electroplating pretreatment of caster Hardware: electroplating

pretreatment of caster hardware

is the basis for electroplating of caster hardware and the key to

ensure product quality. Before

electroplating, the plated substrate of caster hardware is not

treated to the specified requirements,

even if there is a good electroplating solution for five gold parts

of caster, With proper electroplating

parameters of caster hardware, equipment and skilled personnel that

can well regulate the

electroplating parameters of caster hardware, it is impossible to

obtain the electrodeposited coating

of caster hardware that meets the quality requirements. Before

electroplating of caster hardware, it

is not only necessary to remove the grease on the base metal and

foreign objects that affect the

coating adhesion and other quality requirements, The oxide on the

surface shall also be removed

to make the surface have the specified cleanliness and certain

activity, so as to ensure the firm

combination of the coating and the substrate. Sometimes, according

to the required appearance

of the electroplated coating of caster hardware, some other special

pre electroplating treatment

of caster Hardware shall be carried out. The executive standard is

GB / t12611-90

2. Electroplating process control of caster hardware. The service

conditions and service life of

electro galvanized metal or components of caster hardware are

closely related to the thickness

of electro galvanized coating of caster hardware. The stricter the

service conditions and the longer

the service life, the thicker the required electro galvanized

coating of caster hardware. Different

products should be used according to the specific environment

(temperature, humidity, rainfall

Atmospheric composition, etc.) determine the plating thickness of

caster hardware with the expected

service life. Blind thickening will cause various wastes. However,

if the thickness is insufficient, it will

not meet the expected service life requirements. Different

manufacturers should first prepare a set

of complete and reasonable process flow to clarify the plating

parameters of caster hardware

according to their own equipment conditions and under the condition

of determining the plating type,

Control the electroplating solution concentration of caster

hardware and carry out standard operation

3. Post plating treatment: Post plating treatment of caster

hardware (passivation, hot melting, sealing

and dehydrogenation, etc.) to enhance the protective performance,

decoration and other special

purposes of the plated parts. After galvanizing, chromate

passivation or other conversion treatment is

generally required, Forming corresponding type of conversion film

is one of the key processes to

ensure the quality after plating. Aging treatment (70 ~ 80oC in the

oven) is better after passivation.

Passivation can be divided into the following forms: (1) Color

Passivation: HNO3, H2SO4 and CrO3

(three acids are indispensable) (2) blue white passivation: F + Cr

(3) silver white passivation: Ba + Cr

(4) black passivation: Cr + Ag or Cr + Cu (5) golden yellow

passivation: Cr + reductant. Color

Passivation: suitable for zincate zinc plating, After passivation,

the part surface is red, green and

slightly yellow (Cr + 6 red, Cr + 3 green), and purple cannot

appear (it indicates that the passivation

film is loose). The simplest method is to rub repeatedly on the

part surface with your fingers for

several times, and there can be no color change (loss). Blue, white

and blunt: because the fluoride in

the passivation solution decreases gradually with time, the blue

color of the part surface will gradually

become lighter, The color of workpieces produced in the same shift

is not well maintained. Therefore,

it is necessary to strictly control the passivation process and pay

attention to the thickness. Silver white

blunt: it does not change with time and the color is consistent

(2) Product quality inspection

1. Strictly implement the current national standards: (1) <

metal coating, Electroplated coating of zinc

castor hardware on iron and steel > GB / T 9799-1997 EQV 250

2081:1986 (2) < chromate conversion

film of electroplated zinc plating and cadmium plating on castor

hardware > GB / T 9800-1988eqv 250

4520:1981 (3) < corrosion test in artificial atmosphere: salt

spray test > GB / t10125-1997 2. Inspection

requirements: both parties shall sign a technical agreement before

production, which shall be carried

out in principle. (1) large parts: each piece must be inspected, No

missing inspection. (2) small parts:

sampling inspection method shall be adopted. 5% of each batch shall

be sampled. If 1% is unqualified,

another 10% shall be sampled. If 1% is still unqualified, the whole

batch shall be unqualified.

(3) inspection procedure: A. appearance inspection: inspect

according to drawings, processes and

standards, and reserve sample standards together with the

manufacturer( Seal with varnish or plastic

film as a comparison sample. There shall be no obvious coating

defects on the main surface of

electroplating parts of caster hardware, such as blistering,

porosity, roughness, crack or no coating

locally, Except for unavoidable coating defects caused by base

metal defects, the plated parts shall

be clean and free of damage, and the coating shall be bright

(unless otherwise specified). B. coating

thickness inspection: use a thickness gauge for inspection. (the

user's requirements are the standard).

(the minimum local thickness is generally specified) coating

thickness for general purposes: 6 = 8 ~

12um. For outdoor use: 6 = 18 ~ 22um. Bolts and nuts: 6 = 3 ~ 6um.

C. the functional positioning of

the coating shall be reasonable : after galvanizing, if there are

no special requirements, the brightness

should not be too high. If it is too high, the brittleness of the

coating increases and the color changes

quickly. It must be reasonable and the amount of brightener should

be controlled. D. There should be

no missing plating, scorching and peeling in the depth of the blind

hole. Color differences are allowed,

and there can be slight scorching at the sharp corners of large

parts. 3 inspection method: under the

irradiation of natural scattered light or two 40W fluorescent

lamps, At 500mm (visual inspection), the

problems found in this state are quality problems. If they are not

found, they are allowable defects

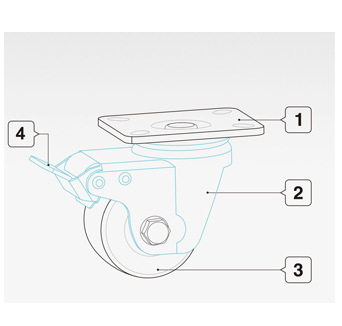

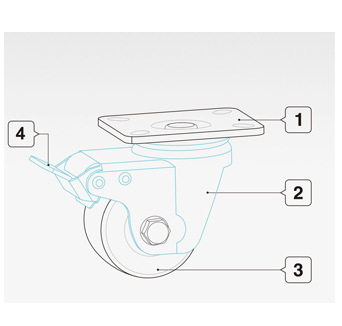

Industrial Swivel Casters Parameter

| Wheel material | Nylon6 |

| Load Capacity | 700KG |

| Wheel Diameter | 75mm |

| Color | white |

| Tread Width | 50mm |

| Load Height | 108MM |

Industrial Swivel Casters Describe

Industrial Swivel Casters Size

Industrial Swivel Casters Material

| Name | Material | Treatment |

| 1 | Caster Seat | Cold-rolled carbon steel | Black Coated/Zn Galvanized |

| 2 | Body | Aluminum alloy | Ivory/Powder Coated |

| 3 | Ball | Bearing Steel | Ni-Cr |

| 4 | Brake | Steel 45 | Zn Galvanized |

| 5 | Pin | Steel 10 | Zn Galvanized |

| 6 | Wheel | PA6 | Black |

Industrial Swivel Casters Scope of application

Application.

Communication equipment, semiconductor manufacturing equipment,

experimental equipment,

medical equipment, printing machines, all kinds of Press, all kinds

of special machinery, all kinds

of variable production equipment, dust-free room equipment,

aluminum frame, equipment, etc.

About us.

KTC (Bejing Korea Technology Caster Co., Ltd.) was founded in 2007.

KTC is a modern

company specialzingin the production of multi function &high

quality CASTER and

KT FOOT based on best design and design technology.

KTC.

The company is headquartered in Niulanshan Industrial Zone,Shunyi

District, Beijing. KTC

adopts international advanced production testing equipments,

professional intelligent

production management system and professional design flow. Now the

company produces

multi function & high quality production, such as KT CASTER and KT

FOOT, among which

high quality of height adjusting CASTER,shockproof type CASTER,

high quality of height

adjusting CASTER, shockproof type CASTER,high load CASTER and level

adjusting FOOT

are widely used in the world's advanced automation equipment and

semiconductor e

quipment industry.

In order to manufacture the world's highest level of products,KTC

use the best processing

technology and equipment. And KTC continuously launches world top

level of new products.

KTC's s also has set up a branch in Korea, so it is favored by

theusers of various fields around

the world.