Casting process flow of cast iron castors

Make mold, core box - sand molding - melting - pouring - sand

falling - de pouring riser cleaning -

Inspection and warehousing. If there are defects after pouring, 1)

the defective products must be

separated, and relevant departments shall be informed to analyze

the causes of defects and

correct them in the next production

2) Analyze whether the defect can be repaired, such as repair

welding. Not all products need

heat treatment. It mainly depends on your product materials and the

use of the product. Heat

treatment is nothing more than to eliminate internal stress or

improve or reduce the hardness

of products for processing. Some guests have special requirements,

which should be analyzed

according to the specific situation.

Technological process of casting production

Casting production is a complex multi process combination process,

which includes the following

main processes:

1) Prepare the production process, formulate the production process

plan and process documents

and draw the casting process diagram according to the part drawing

to be produced, production

batch and delivery time;

2) Production preparation, including preparation of melting

materials, molding and core making

materials and patterns, core boxes, sand boxes and other process

equipment;

3) Molding and core making;

4) Melting and pouring;

Forming principle casting production is to heat and melt the metal

to make it flow, then pour it into

the mold cavity with a certain shape, and fill the mold cavity

under the action of gravity or external

force (pressure, centrifugal force, electromagnetic force, etc.), A

metal forming method that cools

and solidifies into caster castings (or parts). 1 in the casting

forming process, caster castings are

generally cut into parts as blanks. However, many castor castings

can meet the design accuracy and

surface roughness requirements of parts without machining, and can

be directly used as parts.

Performance and composition of molding sand 1. Performance of

molding sand the main performance

requirements of molding sand (including core sand) include

strength, air permeability, fire resistance,

yield, fluidity, compactness and collapsibility. 2. Composition of

molding sand molding sand is

composed of raw sand, adhesive and additives. Raw sand for casting

requires sea sand, river sand

or mountain sand with less mud content, uniform particles and

circular and polygonal shape.

Adhesives for casting include clay (ordinary clay and bentonite),

sodium silicate sand, resin,

synthetic oil and vegetable oil, which are called clay sand, sodium

silicate sand, resin sand, synthetic

oil sand and vegetable oil sand respectively. In order to further

improve some properties of mold

(core) sand, some additives, such as coal, sawdust, pulp and so on,

are often added to mold (core)

sand. Molding sand structure, br > 2 molding sand structure

process characteristics casting is one of

the main methods to produce parts blank, especially for parts blank

of some brittle metal or alloy

materials (such as various iron castings, non-ferrous alloy castor

castings, etc.), casting is almost the

only processing method. Compared with other processing methods, the

casting process has the

following characteristics: 1) castor castings can not be limited by

metal materials, size and weight.

Castor casting materials can be various cast iron, cast steel,

aluminum alloy, copper alloy, magnesium

alloy, titanium alloy, zinc alloy and various special alloy

materials; Caster castings can be as small as a

few grams and as large as hundreds of tons; The wall thickness of

castors can be from 0.5mm to 1m;

Caster casting length can range from a few millimeters to more than

ten meters. 2) Casting can

produce all kinds of blanks with complex shapes, especially

suitable for producing parts with complex

cavities, such as all kinds of boxes, cylinders, blades, impellers,

etc. 3) The shape and size of castor

castings can be very close to the parts, which not only saves metal

materials, but also saves cutting

hours. 4) Castor castings generally use a wide range of raw

materials and low cost. 5) With flexible

casting process and high productivity, it can be produced manually

or mechanically.

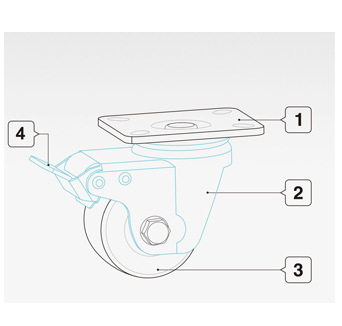

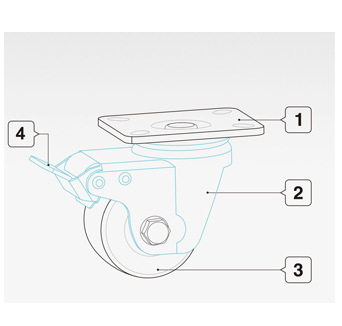

Industrial Swivel Casters Parameter

| Wheel material | Nylon6 |

| Load Capacity | 600KG |

| Wheel Diameter | 63mm |

| Color | white |

| Tread Width | 50mm |

| Load Height | 96MM |

Industrial Swivel Casters Describe

Industrial Swivel Casters Size

Industrial Swivel Casters Material

| Name | Material | Treatment |

| 1 | Caster Seat | Cold-rolled carbon steel | Black Coated/Zn Galvanized |

| 2 | Body | Aluminum alloy | Ivory/Powder Coated |

| 3 | Ball | Bearing Steel | Ni-Cr |

| 4 | Brake | Steel 45 | Zn Galvanized |

| 5 | Pin | Steel 10 | Zn Galvanized |

| 6 | Wheel | PA6 | Black |

Industrial Swivel Casters Scope of application

Application.

Communication equipment, semiconductor manufacturing equipment,

experimental equipment,

medical equipment, printing machines, all kinds of Press, all kinds

of special machinery, all kinds

of variable production equipment, dust-free room equipment,

aluminum frame, equipment, etc.

About us.

KTC (Bejing Korea Technology Caster Co., Ltd.) was founded in 2007.

KTC is a modern

company specialzingin the production of multi function &high

quality CASTER and

KT FOOT based on best design and design technology.

KTC.

The company is headquartered in Niulanshan Industrial Zone,Shunyi

District, Beijing. KTC

adopts international advanced production testing equipments,

professional intelligent

production management system and professional design flow. Now the

company produces

multi function & high quality production, such as KT CASTER and KT

FOOT, among which

high quality of height adjusting CASTER,shockproof type CASTER,

high quality of height

adjusting CASTER, shockproof type CASTER,high load CASTER and level

adjusting FOOT

are widely used in the world's advanced automation equipment and

semiconductor e

quipment industry.

In order to manufacture the world's highest level of products,KTC

use the best processing

technology and equipment. And KTC continuously launches world top

level of new products.

KTC's s also has set up a branch in Korea, so it is favored by

theusers of various fields around

the world.