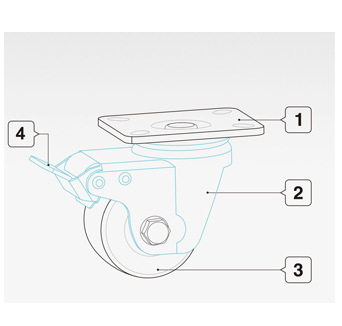

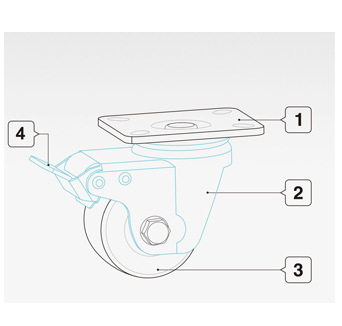

Low Profile Industrial Top Plate Locking Caster Wheels with Brake

KT-LGP1-75SF

Types of equipment punches in Caster Factory

Types of caster punch

1. According to the driving force of the slider, it can be divided

into mechanical type and hydraulic

type, so the caster punch is divided into:

(1) Mechanical caster punch (2) hydraulic caster punch

In general sheet metal stamping, most of them use mechanical caster

punch. Hydraulic caster punches

have hydraulic caster punches and hydraulic caster punches

according to their different liquids. At

present, hydraulic caster punches account for the majority, while

hydraulic caster punches are mostly

used for large machinery or special machinery.

2. Classification according to sliding block movement mode:

According to the movement mode of the sliding block, there are

single acting, compound acting and

three acting caster presses. Only the single acting caster press

with one sliding block is the most

used at present. Compound acting and three acting caster presses

are mainly used in the extension

processing of automobile body and large processed parts, and their

number is very small.

3. Classification according to slider driving mechanism

(1) Crankshaft caster punch

The caster punch using crankshaft mechanism is called crankshaft

caster punch. As shown in Figure

1, it is crankshaft caster punch. Most mechanical caster punches

use this mechanism. The reason

why the crankshaft mechanism is used most is that it is easy to

make, can correctly determine the

lower end position of the stroke, and the motion curve of the

slider is generally suitable for all kinds

of processing. Therefore, this type of stamping is suitable for

punching, bending, stretching, hot

forging, warm forging, cold forging and almost all other caster

punch machining.

(2) Crankshaft free caster punch

Crankshaft free caster punch, also known as eccentric gear caster

punch, figure 2 is eccentric gear

caster punch. The comparison of the functions of the two structures

of the crankshaft caster punch

and the eccentric gear caster punch is shown in Table 2. The

eccentric gear caster punch structure

is superior to the crankshaft structure in terms of shaft rigidity,

lubrication, appearance and

maintenance, but the disadvantage is that the price is high. When

the stroke is long, the eccentric

gear caster punch is more favorable, and when the stroke of the

special punching machine is short,

the crankshaft caster punch is better. Therefore, small machines

and high-speed punching caster

punch are also the field of crankshaft caster punch.

(3) Elbow type caster punch

The one who uses the toggle mechanism on the slider drive is called

the toggle caster punch, as

shown in Figure 3. This caster punch has a unique slider motion

curve that the slider speed near

the bottom dead center will become very slow (compared with the

crankshaft caster punch), as

shown in Figure 4. It also correctly determines the dead center

position under the stroke.

Therefore, this caster punch is suitable for compression processing

such as embossing and finishing.

Now cold forging is used most.

(4) Friction caster punch

The caster press using friction transmission and screw mechanism on

track drive is called friction caster

press. This caster punch is most suitable for forging and crushing

operations. It can also be used for

bending, forming and stretching. It has multi-purpose functions. It

was widely used before the war

because of its low price. Due to the inability to determine the

lower end of the stroke, poor machining

accuracy, slow production speed, overload caused by wrong control

operation, and the need for skilled

technology in use, it is gradually being eliminated

(5) Screw caster punch

Screw type caster punch (or screw caster punch) is used in slider

drive mechanism

(6) Rack type caster punch

The use of rack and pinion mechanism on the slider driving

mechanism is called rack caster punch.

Screw caster punch and rack caster punch have almost the same

characteristics, and their

characteristics are roughly the same as those of hydraulic caster

punch. It used to be used for pressing

bushings, debris and other articles, oil pressing, baling, and

pressing out of cartridge cases (hot room

thinning), but now it has been replaced by hydraulic caster punch,

which is no longer used except under

very special circumstances.

(7) Connecting rod caster punch

The caster punch that uses various linkage mechanisms on the slider

driving mechanism is called

connecting rod caster punch. The purpose of using the connecting

rod mechanism is to keep the

stretching speed within the limit while shortening the processing

cycle. By reducing the speed change of

the stretching processing, the speed of the approach travel from

the top dead center to the processing

start point and the return travel from the bottom dead center to

the top dead center can be accelerated,

so that it has a shorter cycle than the crankshaft caster punch, so

as to improve the productivity. This

caster punch has been used for deep drawing of cylindrical

containers since ancient times, and the

table top is narrow. Recently, it has been used for processing the

main panel of automobile, and the

table top is wide.

(8) Cam caster punch

The caster punch using cam mechanism on the slider driving

mechanism is called cam caster punch.

The caster punch is characterized by making an appropriate cam

shape so that the desired slider

motion curve can be easily obtained. However, due to the nature of

cam mechanism, it is difficult to

convey large force, so the capacity of this caster punch is very

small.

Industrial Swivel Casters Parameter

| Wheel material | Nylon6 |

| Load Capacity | 700KG |

| Wheel Diameter | 75mm |

| Color | white |

| Tread Width | 50mm |

| Load Height | 108MM |

Industrial Swivel Casters Describe

Industrial Swivel Casters Size

Industrial Swivel Casters Material

| Name | Material | Treatment |

| 1 | Caster Seat | Cold-rolled carbon steel | Black Coated/Zn Galvanized |

| 2 | Body | Aluminum alloy | Ivory/Powder Coated |

| 3 | Ball | Bearing Steel | Ni-Cr |

| 4 | Brake | Steel 45 | Zn Galvanized |

| 5 | Pin | Steel 10 | Zn Galvanized |

| 6 | Wheel | PA6 | Black |

Industrial Swivel Casters Scope of application

Application.

Communication equipment, semiconductor manufacturing equipment,

experimental equipment,

medical equipment, printing machines, all kinds of Press, all kinds

of special machinery, all kinds

of variable production equipment, dust-free room equipment,

aluminum frame, equipment, etc.

About us.

KTC (Bejing Korea Technology Caster Co., Ltd.) was founded in 2007.

KTC is a modern

company specialzingin the production of multi function &high

quality CASTER and

KT FOOT based on best design and design technology.

KTC.

The company is headquartered in Niulanshan Industrial Zone,Shunyi

District, Beijing. KTC

adopts international advanced production testing equipments,

professional intelligent

production management system and professional design flow. Now the

company produces

multi function & high quality production, such as KT CASTER and KT

FOOT, among which

high quality of height adjusting CASTER,shockproof type CASTER,

high quality of height

adjusting CASTER, shockproof type CASTER,high load CASTER and level

adjusting FOOT

are widely used in the world's advanced automation equipment and

semiconductor e

quipment industry.

In order to manufacture the world's highest level of products,KTC

use the best processing

technology and equipment. And KTC continuously launches world top

level of new products.

KTC's s also has set up a branch in Korea, so it is favored by

theusers of various fields around

the world.